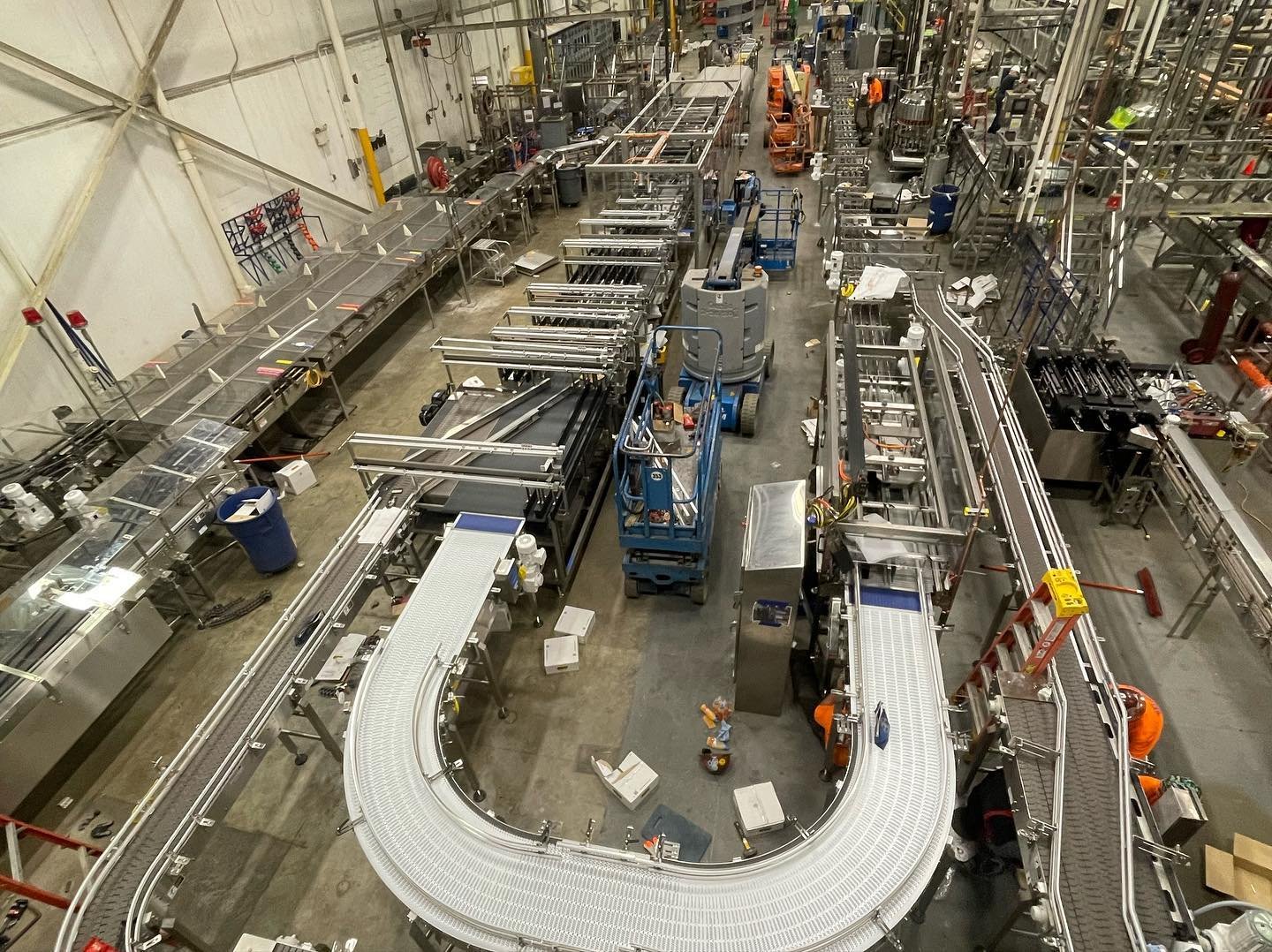

Stainless Steel Fabrication Facility

Heritage Industrial Services recently completed a successful rigging and installation project for a customer specializing in custom stainless-steel fabrication. The customer required assistance with relocating and installing their equipment at their new manufacturing facility.

Our team provided turnkey services, handling everything from the initial installation of equipment utilities to each piece’s final leveling, aligning, and anchoring. This comprehensive approach ensured a smooth and efficient transition for the customer.

Location:

NJ

Industry:

Industrial Manufacturing

THE CHALLENGE

The scope of work included:

- 2 – Stackmaster units

- Rapido 32

- FS32 (x-space) folder

- Upender

- QXS16C Decoiler

- Rollformer

- TD150 (40′ long, approximately 40,000 lbs.)

- Unloader for TD150

THE EXECUTION

To facilitate the safe and precise installation, we utilized the following equipment:

- (2) 15K Capacity Hyster Forklifts

- (1) 25/35 Versa-Lift

- Specialized Non-Marking Rigging Skates

- Misc Rigging Gear

- Flatbed and Conestoga trailers

This project demonstrates Heritage’s commitment to providing our customers with high-quality, efficient, safe rigging and installation services. We are proud to have successfully assisted our customer in relocating their operations to their new facility.