Food and Beverage Plant Maintenance Project

Heritage’s skilled millwright crew completed a critical plant maintenance project, demonstrating their expertise in various tasks.

Heritage completed the entire project within a demanding three-day outage window, ensuring minimal disruption to plant operations. The team demonstrated effective project management while prioritizing workforce well-being by strictly following safety protocols and meeting critical path schedule deadlines.

Location:

NJ

Industry:

Food and Beverage

THE CHALLENGE

The project involved:

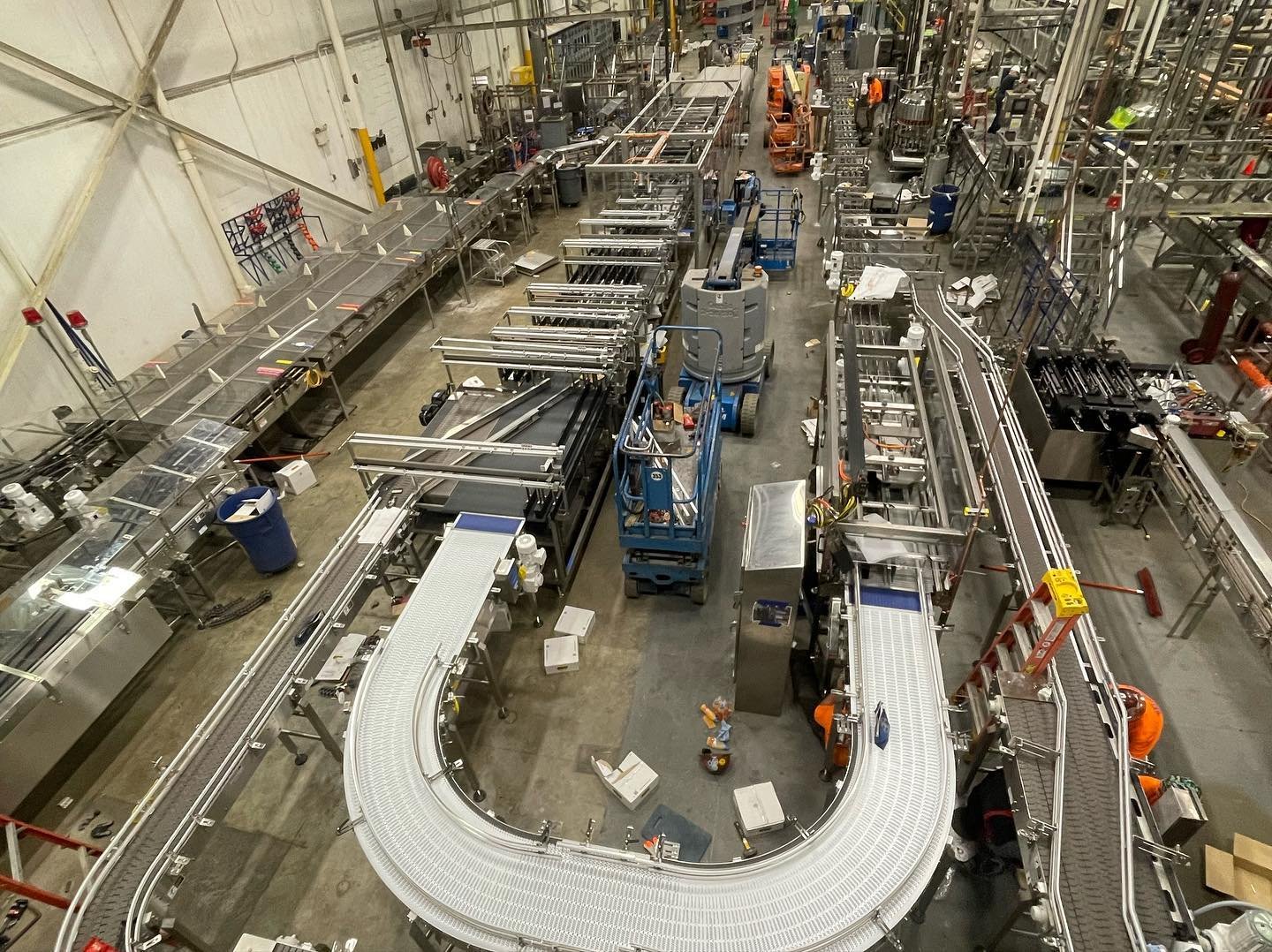

- Offloading and rigging of heavy machinery, including a Krones labeler, a Douglas Machine Bundler, various conveyors, and other auxiliary equipment

- Precise placement and installation of the equipment within the plant

- Identification and removal of idle and surplus equipment

- Repurposing of the removed equipment through Heritage’s asset recovery network, resulting in significant cost savings for the client

THE EXECUTION

This successful project further solidifies Heritage’s position as a preferred provider of rigging and millwright services, demonstrating its ability to deliver complex projects safely, efficiently, and within budget.