Rigging & STEEL ERECTION AT THE SEACOURT PAVILION

Heritage Industrial Services was contracted to perform this rather unique project. The scope included the prep, rigging, and removal of a visual landmark in the Toms River, NJ area and subsequent installation of new structural steel and decking. The lookout dome atop the Seacourt Pavilion needed to be removed as part of upgrades to the upper section of the retail center. It had stood for many years, but due to damage sustained from Hurricane Sandy and poor design it would leak significantly whenever it rained. In addition, all of this was to occur as the pavilion was open to its many businesses and customers served on any given day.

After an initial walk thru and meeting with the customer, it was determined that the most cost-effective method to remove the dome would be in one piece. This would alleviate the need to demo the structure from an unsafe working height above planned new construction operations.

Heritage crews began by prepping the interior of the domed structure utilizing a scaffold tower to reach the 65’ height inside of the dome. Heritage crew members also prepared the existing structural steel for removal, utilizing torches and expert skill, so as to not damage any steel that was to remain. Heritage had performed pick planning/engineering prior to beginning the project and chose a 130 Ton crane for the pick. The day of the pick the area around the work zone was safed off as a precaution to prevent intrusion by pedestrians. Utilizing trained and certified riggers/millwrights, Heritage crew members picked the dome with zero issues and lowered it to the ground. Immediately, the crew switched from a dismantling mode to installing the new infill structural steel and decking. Given the fact that a winter storm was fast approaching, covering the hole in the roof was paramount. Heritage crew members returned the next day to finish the infill install and left the client with a new storm proof deck to roof over just hours before snow began falling.

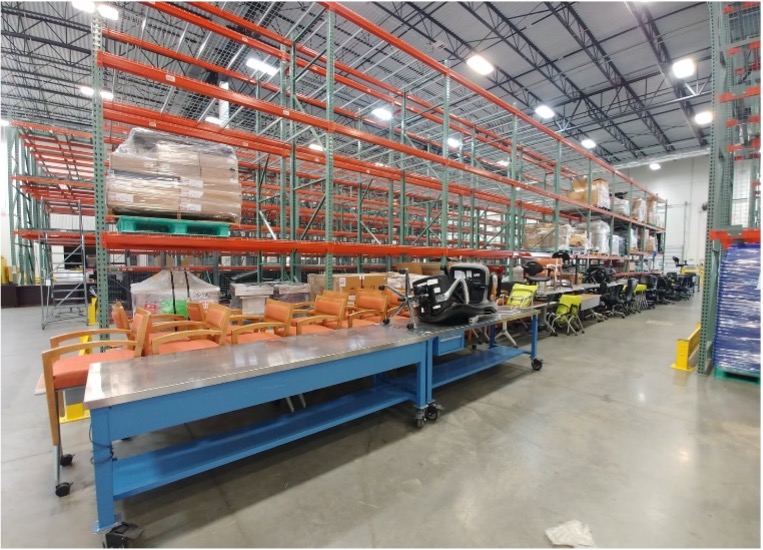

Since this work was completed, we have been back installing numerous structural steel segments within the building’s interior.